Super Deck (DS-953)

Faisal Shine - Super Deck (DS-953)

Specialists in the design, production and installation of profile metal decking.

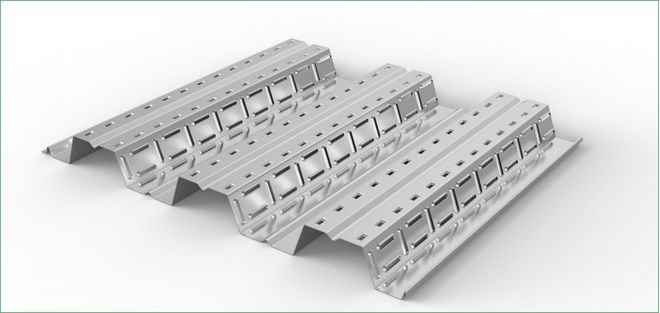

In response to the growing demand for a Composite Metal Deck flooring system in India, FAISALROOFING have developed a range of new profile unique and a true steel concrete composite DECK for the Indian construction market. Super Deck with special in built shear connectors of bonding of concrete with DECK sheets.

Brief

Super Deck is a cold formed corrugated steel sheet supported by steel joists or beams. It is used to support concrete or insulating membrane of a roof. It has been designed and developed to provide a structurally

efficient product for use in roof and floor systems.

Super Deck is also known as Composite deck, it has embossments in the vertical ribs that bond with the concrete slab to develop a composite floor system. Composite deck acts as a form during the concrete pour.

SUPER DECK is a long-span composite floor system that blends steel's speed and versatility with concrete's performance and durability.

Benefit's of Super Deck

Load Capacity

The performance of composite decked slabs is assessed from dynamic load tests carried out in accordance with BS5950 Part 4 and Eurocode 1994-1-1.

Excellent load capacities up to, and in some cases exceeding 15kN/m2 can be achieved due to the shear bond developed between the concrete and the embossed metal decking.

The relatively shallow slabs are typically between 130-200mm deep with light mesh reinforcement for crack control and fire.

Additional reinforcement may be required in some areas to enhance load capacity or due to exposure conditions.

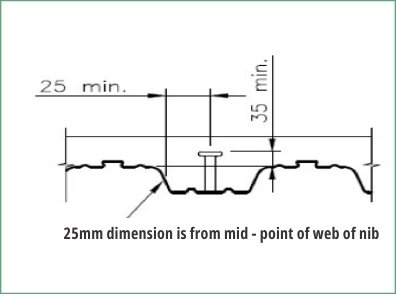

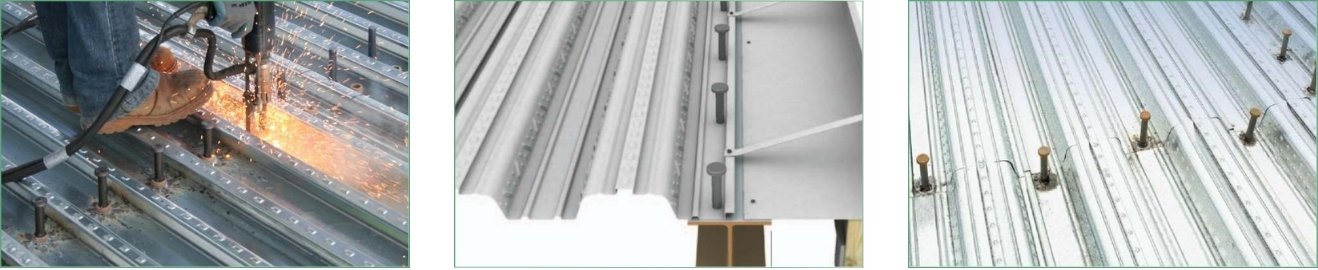

Shear Stud

Composite beams are typically hot rolled steel sections that act compositely with a concrete slab. Shear studs are required to transfer force between the steel section and the concrete slab. The studs are

welded to the beam, normally through the deck sheet.

This enables the concrete slab to act like a large top flange to the composite beam when the concrete has hardened and creates a stronger section to support the loadings applied to the finished slab

When installing shear studs, the length after weld should extend at least 35 mm above the top of the main rib of the deck profile.

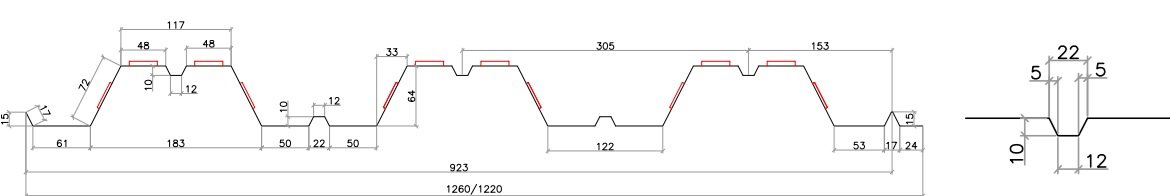

Super Deck - Specification

| Thickness mm | Material | Grade of Steel / MPa | Profile Geometry |

|---|---|---|---|

| 0.80 - 2.00 |

CRCA, Galvanised, GP Skin Pass, PPGI for special purpose |

250 - 350 Mpa YS | Depth : 64 +/-2mm |

| Pitch : 305 +/- 5mm | |||

| Cover Width : 923 +/-10mm | |||

| Overall width : 953 +/- 10mm | |||

|

Length upto 13m as per site requirement |

Technical Submission - Super Deck

| Sr. No. | Thickness mm | unit/weight Kg/m^2 | Moment of Inertia cm^4 | Section Modulus cm^3 |

|---|---|---|---|---|

| 1 | 0.8 | 7.85 | 83.71 | 28.14 |

| 2 | 0.9 | 8.83 | 94.06 | 31.63 |

| 3 | 1 | 9.81 | 104.38 | 35.11 |

| 4 | 1.2 | 11.78 | 124.91 | 42.05 |

| 5 | 1.35 | 13.25 | 140.23 | 47.23 |

| 6 | 1.5 | 14.72 | 155.46 | 52.39 |

Allowable Loads in kg/m^2 for material Fy = 250 Mpa

| Sr. No. | Thickness mm | SPAN IN meters | |||||

|---|---|---|---|---|---|---|---|

| 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.5 | ||

| 1 | 0.8 | 2948 | 2166 | 1658 | 1310 | 1061 | 679 |

| 2 | 0.9 | 3294 | 2420 | 1853 | 1464 | 1186 | 759 |

| 3 | 1 | 3657 | 2686 | 2057 | 1625 | 1316 | 842 |

| 4 | 1.2 | 4380 | 3218 | 2463 | 1946 | 1576 | 1009 |

| 5 | 1.35 | 4919 | 3614 | 2767 | 2186 | 1771 | 1133 |

| 6 | 1.5 | 5457 | 4009 | 3069 | 2425 | 1964 | 1257 |

Allowable Loads in kg/m^2 for material Fy = 345 Mpa

| Sr. No. | Thickness mm | SPAN IN meters | |||||

|---|---|---|---|---|---|---|---|

| 1.2 | 1.4 | 1.6 | 1.8 | 2 | 2.5 | ||

| 1 | 0.8 | 3852 | 2830 | 2167 | 1712 | 1386 | 887 |

| 2 | 0.9 | 4330 | 3181 | 2435 | 1924 | 1558 | 997 |

| 3 | 1 | 4806 | 3531 | 2703 | 2136 | 1730 | 1107 |

| 4 | 1.2 | 5756 | 4229 | 3238 | 2558 | 2072 | 1326 |

| 5 | 1.35 | 6466 | 4750 | 3637 | 2873 | 2327 | 1489 |

| 6 | 1.5 | 7172 | 5269 | 4034 | 3187 | 2582 | 1652 |

APPLICATIONS