PUF Roof & Wall Panels

FAISAL SHINE - PUF ROOF & WALL PANEL

Industrial Construction of Faisal Shine-PUF Roof & Wall Panels:

Metal-faced polyurethane sandwich panels are the system of choice today for large industrial building, refrigerated warehouse, office blocks, exhibition halls, fair pavilions, schools and sports halls

The aluminium or steel facings themselves are surface coated can be manufactured with profiles of various depths leading to a high load bearing. Polyurethane sandwich panels come complete with specially formed toungue-and-groove joints ensuring a perfect fit and maximum integrity.

Assembly is fast, easy and coast effective. The resultant sandwich panel has a load-dearing capability many times greater than that achieved by adding together the loadbearing capacities of the individual layers.

As a result, these thin relatively lightweight sandwich panels can be safely bridge wide spans. For example, a panel just 100 mm thick can easily bridge a clear spam of some 6 meters.

Energy Efficiency

Width 80 mm thickness sandwich panels with polyurethane rigid foam, the U valve is 0.297 W/(M2K). In comparisons, a solid wall with 24 cm thick masonry and 2 cm plaster walls has U valve of 1.85 W/(M2K).

Rigid polyurethane foam combines excellent thermal insulation properties with good mechanical strength, making it an outstanding construction material that does not rot, mold-resistant, odorless and non-toxic for all conceivable applications. The foam is resistant to the chemicals typically used in construction and is compatible with most solvent-containing adhesives, paints and wood preservatives.

Polyurethane rigid foam is extremely durable and can be installed easily and securely, ensuring cost-effective, efficient construction.

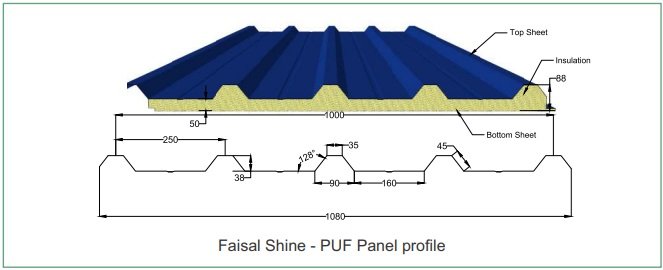

FAISAL SHINE - PUF ROOF PANEL

Specifications:

Faisal shine - Pre-fabricated roofing panels are made of polyurethane foam (PUF) sandwiched between layers of waterproof and non-corrosive material. These pre-fabricated roofing panels are designed to withstand the quirks of nature and the vagaries of time.

Faisal Shine effectively restricts the transmission of heat by 5-6 degrees, and also absorbs and reduces the noise of rain as well. These roofing panels are aesthetically designed, sound-proof and weather-resistant. Being corrosionfree, these panels require low maintenance and durable in nature, making them a cost-effective roofing solutions.

Specifications:

Faisal shine, a leader with over 10 years of engineering experience in cooling and construction solutions brings you secondary roofing panels. A first time concept in India, these panels:

Application:

Features:

| Dimensional Stability: | <1 per cent for -48h @ -30 ºC |

|---|---|

| Working Temperature | -90 ºC or +90ºC |

| Adhesion Strength | 100 Kpa |

| Compressive Strength | 120 Kpa |

| Thermal Conductivity | u= 0.020 W/ M 0 k |

| Metal Laminates | Pre-painted galvanised steel (PPGS) |

| Insulation | Rigid PUF |

| Normal density | 35-40 kgs/ m3 |

| Joinery | Overlap joinery with stitch screw and EPDM washers, Butyl sealants for leak-proof construction |

| Normal Panel Width | 1000 mm |

| Panel Length | Single panel up to 12000 mm |

FAISAL SHINE - PUF WALL PANEL

Building Efficiency, Aesthetically:

Faisal shine insulated pre-fabricated sandwich panel systems are made from rigid polyurethane foam (RPUF), which can be customized and easily transported. They are also ecologically and economically sustainable.

Faisal shine creates clean, dust-proof, and power-saving structures with high temperature insulation. Being modular, they can be free-standing or supported along steel structural. Specially engineered versions are available for walk-on ceilings, insulated roofing, walls and floors.

Faisal shine comes with all utilities like doors, view glasses and construction accessories.

Specifications:

Steel faced polyurethane insulated composite panels are designed to provide a fast, efficient and cost effective clean construction system. These panels are of CFC free normally faced on both sides with a 0.5 mm thick precoated galvanised steel sheet with edges are vertically lipped by 24mm. The panels have single tongue and grooved joints to provide a secure and consistenct joint. These joints are further sealed with silicon for a continuons anti-bacterial barrier

Module: Panel Width: 1023mm

Construction Width: 1000mm

Insulation: Rigid Polyurethane foam (RPUF)

Density = 40Kg/m3 ±2 Kg/m3

Features:

| Metal Laminates / Beltings | Pre-Painted Galvanized Steel (PPGS) |

|---|---|

| Insulation | Rigid Polyurethane Foam(RPUF) |

| Special Finished | Aluminum/ SS /Plastisol |

| Suspension System | Powder-Coated |

| Thermal Conductivity | u= 0.020 W/ M 0 k |

| System | Extruded AL System |

| Normal density | 35-40 kgs/m3 |

| Panel Thickness | 60 / 80 / 100 / 125 / 150mm |

| Normal Panel Width | 1000 mm |

| Panel Length | Transportable length |

| Covings | Food grade PVC coving with accessories |

| Panel Joinery | Continuous slip lock, tongue and groove |

| Dimensional Customized | As per customer specification |