Rockwool & Glasswool

FAISAL SHINE- ROCKWOOL & GLASSWOOL

FAISAL SHINE - ROCKWOOL AND GLASSWOOL INSULATIONS

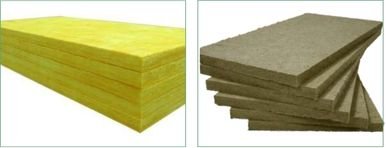

Rockwool is made from stone and glass, Glasswool is made from glass fibers. Both are heated to very high temperatures until it melts, and is then spun quickly to create fibers. These fibers are then bound together to be used as insulation. The color of glasswool is bright yellow, and rockwool is dark. Because of the difference of the raw materials, rockwool has a bigger density than glasswool. But, glasswool has a wider choice for thickness. Because of the difference in density, rockwool has a much better fire-resistance character than glasswool.

SPECIFICATION:

| Item | Glasswool | Rockwool |

|---|---|---|

| Density (kg/m3) | 10-50 | 50-200 |

| Thickness (mm) | 20-200 | 30-100 |

| Temperature (°C) | 230 - 260 | 700 - 850 |

FEATURES AND BENEFITS:

Glasswool and Rockwool make a significant contribution to ensuring safe workplaces by providing:

FAISAL SHINE - ROCKWOOL AND GLASSWOOL SANDWICH PANELS:

The top and bottom surfaces sandwich panel is pre-painted galvanized or Galvalume steel. The core material is Rockwool or Glasswool insulation between the both surfaces with very high Strength and density. This sandwich panel is featured with full anti-firing, more heating and sound insulation.

ROCKWOOL PROPERTIES:

| PRODUCT | GLASSWOOL Panels | ||||

|---|---|---|---|---|---|

| Width-wall | 1170mm | ||||

| Width-roof | 1000mm | ||||

| Core thickness (mm) | 50 | 60 | 80 | 100 | 120 |

| K value (W/m °K) | 0.72 | 0.67 | 0.46 | 0.36 | 0.28 |

| R Value (Btu/hr/ft /°F) | 8 | 10 | 13 | 16 | 20 |

| Top and bottom surfaces | PPGI/PPGL | ||||

| Density (Kg/m ) | 100 Kg/m | ||||

| Thermal Conductivity at 10° C mean temperature (w/m k) | 0.04 | ||||

| Compressive Strength at 10% Deformation (Kg/cm ) | 0.50985 | ||||

| Bending Strength (Kg/cm2) | 0.7647 | ||||

| Melting Point | 1000ºC | ||||

| Water Absorption (Volume %) | Less than 1% | ||||

| Sound Reduction (db) | 28-30 | ||||

| Fire Class | Non-Combustible | ||||

GLASSWOOL PROPERTIES

| Width-wall | 1170mm | ||||

|---|---|---|---|---|---|

| Width-roof | 1000mm | ||||

| Core thickness (mm) | 50 | 60 | 80 | 100 | |

| K value (W/m °K) | 0.89 | 0.67 | 0.43 | 0.36 | |

| R Value (Btu/hr/ft /°F) | 14 | 1 | 21 | 27 | |

| Top and bottom surfaces | PPGI/PPGL | ||||

| Density (Kg/m ) | 48 Kg/m | ||||

| Thermal Conductivity at 10° C mean temperature (w/m k) | 0.033 | ||||

| Compressive Strength at 10% Deformation (Kg/cm ) | 0.4896 | ||||

| Recovery After Compression | 90% min. | ||||

| Service temperature | -50°C to +250°C | ||||

| Water Absorption (Volume %) | Less than 2% in accordance with IS: 3144/BS: 3978 | ||||

| Sound Reduction (db) | 28-30 | ||||

| Fire Class | Non-Combustible | ||||

APPLICATIONS:

Because of the difference in heat resistance, glasswool is usually used in common buildings, shops and hospital which do not have special requirement in fire-resistant. For some industry, which has high requirement for heat resistance, such as steelmaking boiler, is more suitable for rockwool.

Mainly usage: Industrial plants, warehouses, public facilities, exhibition centers, shopping malls, cold storage, and a variety of indoor playgrounds, sports grounds.

Main function: Energy-saving insulation, noise control, improve indoor air quality