Polycarbonate Roofing Sheet

FAISAL LITE - POLYCARBONATE ROOFING SHEETS

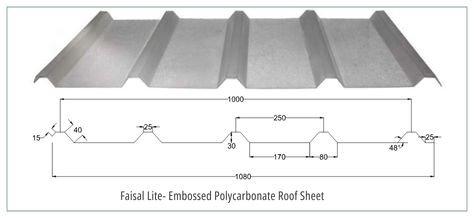

FAISAL LITE- EMBOSSED POLYCARBONATE ROOF SHEET

We feel immensely pleased in offering an exclusive gamut of Faisal Lite - Embossed Polycarbonate Sheet in the industry.

We are one of the major suppliers and traders of Embossed Polycarbonate Sheets in the market. These are solid polycarbonate sheets with a texture on one surface. The purpose of texturing is to provide light diffusion and prevent see-through vision deemed necessary for a variety of applications. These textures enables the diffusion of natural light streaming in along with ascertaining uniform dispersion of light a large area.

SPECIFICATION

| THICKNESS | ||||

|---|---|---|---|---|

| 1.5mm | 1.8mm | 2mm | 2.5mm | 3mm |

| LENGTH | ||||

|---|---|---|---|---|

| As per customer requirement | ||||

| WIDTH | ||||

|---|---|---|---|---|

| Cover width | 1000mm | |||

| Profile width | 1080mm | |||

PROPERTIES & ADVANTAGES:

(Ul94 V0, V2 Flame

ratings) superior

printability

STANDARD SPECIFICATION:

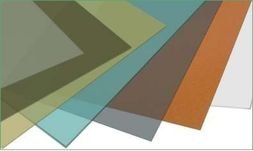

| CLASSIFICATION | MODEL | COLOR | SPECIFICATION / T × W × L, UNIT : MM |

|---|---|---|---|

| Solid Sheet, Roll | HG00 | CLEAR | - Thickness: 2.0~20.0 - Width : 1,000~2,100 (Other specification available upon request) - Length : Order made |

| Hg10 | BLUE GREEN | ||

| Hg11 | LIGHT GREEN | ||

| HG13 | DARK GREEN | ||

| HG17 | DARK BLUE | ||

| HG21 | LIGHT SKY BLUE | ||

| HG30 | WHITE | ||

| HG40 | BROWN | ||

| Hg44 PALE | LIGHT BLUE SMOG | ||

| Hg70 | YELLOW | ||

| HE00 EMBO | CLEAR | ||

| HE11 EMBO | LIGHT GREEN | ||

| HE13 EMBO | DARK GREEN |

FAISAL LITE- COMPACT POLYCARBONATE ROOF SHEET

Being one of the reputed organizations in the industry, we are actively involved in offering a beautiful range of Faisal Lite-Compact Polycarbonate Sheet to our clients.

These sheets are available in various alluring designs and optimum finishing following the precise demands and needs of our clients. Owing to its sturdy designs and excellent finish, these products are extensively demanded and appreciated by a huge numbers of clients. Our offered products can be availed from us in different textures and range.

POLYCARBONATE COATING:

| TYPE | EFFECTIVENESS | APPLICATIONS | REMARK |

|---|---|---|---|

| Hard Coating Antistatic | Surface hardness up Surface antistatic | Sound-proof wallcomputer protective glass | Pencil hardness H~2H |

| Anti-fog Coating | Anti-fogging | Semiconductor clean room | Surface resistance value 106~1012Ω, cm |

| Goggle |

APPLICATIONS:

SPECIFICATION:

TECHNICAL DATA:

| PROPERTIES | TEST METHOD | UNIT | VALUE | UNIT | VALUE | ||

|---|---|---|---|---|---|---|---|

| Physical Properties | Specific Gravity | ASTM D792 | - | 1.20 | - | 1.20 | |

| Water Absorption, 23°C, 24 hr | ASTM D570 | % | 0.20 | % | 0.20 | ||

| Refractive Index | ASTM D542 | - | 1.59 | - | 1.59 | ||

| Optical Properties | Transmittance | ASTM D1003 | % | 86 | % | 86 | |

| Haze | ASTM D1003 | % | 1.0 | % | 1.0 | ||

| Yellowness | ASTM D1925 | YI | 2.0 | YI | 2.0 | ||

| Mechanical Properties | Tensile Strength | ASTM D638 | psi | 9500 | Mpa | 65.0 | |

| Elongation | ASTM D638 | % | 100 | % | 100 | ||

| Flexural Strength | ASTM D790 | psi | 14000 | Mpa | 96.0 | ||

| Flexural Modules | ASTM D790 | psi | 332000 | Mpa | 2289 | ||

| zod Impact Strength(@ 3mm) | ASTM D256 | t-lbs / in | 16.0(P) | J/m | 854.4(P) | ||

| Rockwell Hardness | ASTM D785 | R Scale | 115 | R Scale | 115 | ||

| Thermal Properties | Loaddeformation Temperature | (@ 1.820 Mpa) | ASTM D648 | °F | 275 | °C | 135 |

| (@ 0.455 Mpa) | 284 | 140 | |||||

| Coefficient of thermal expansion | ASTM D696 | in/in/°F | 3.75×10-5 | cm/cm/°C | 6×10-5 | ||

| Flammability | UL 94 | - | V0, V2 | - | V0, V2 | ||

● The above in formation is typical values only, not for warranty purpose.

OUR PRODUCT RANGE

- Roofing Sheets Manufactures in Mumbai

- Roofing Sheets Manufactures in Thane

- Roofing Sheets Manufactures in Navi Mumbai

- Roofing Sheets Manufactures in Nashik

- Roofing Sheets Manufactures in Pune

- Roofing Sheets Manufactures in Goa

- Roofing Sheets Manufactures in Ahmedabad

- Roofing Sheets Manufactures in Vadodara