Aluminium Sheets

Faisal Shine - Aluminium Sheet

Faisal Shine - Aluminium Sheet:

Aluminium is a silvery, white, soft, non-magnetic, ductile material in the boron group. Aluminium sheet can be easily shaped, rolled, drawn extruded, welded therefore it is the ideal material for construction. Aluminium sheet weight is one third of iron sheet and three times greater elongation than iron. Aluminium sheet is near to zero maintenance cost in combination with low specific weight that make the ideal choice.

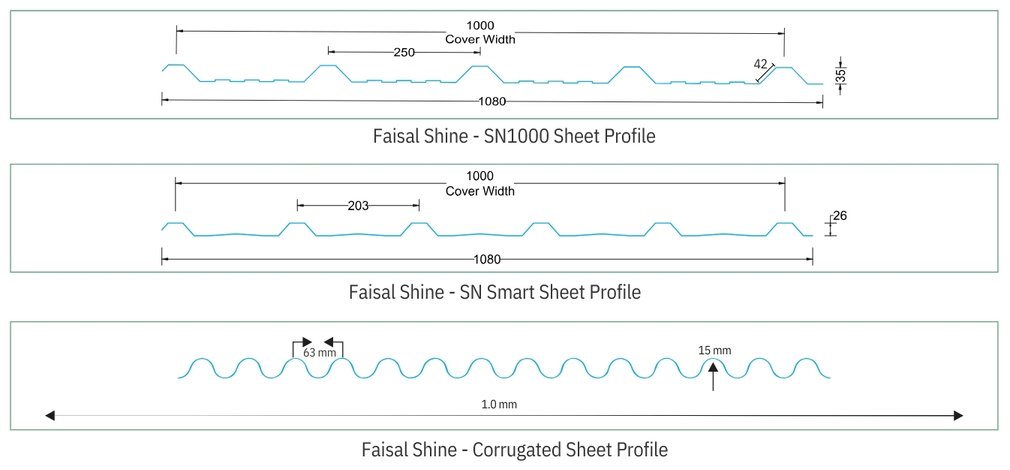

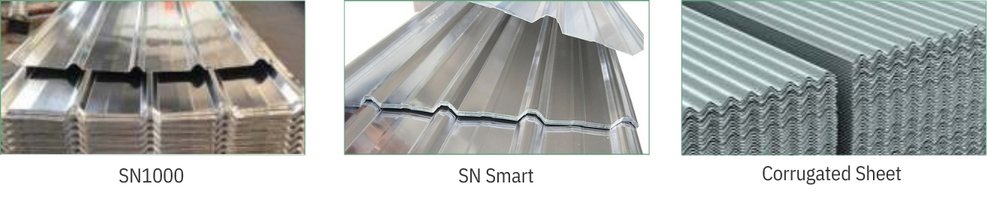

Profile:

Properties:

| Property | Value |

|---|---|

| Atomic Number | 13 |

| Atomic Weight (g/mol) | 26.98 |

| Valency | 3 |

| Crystal Structure | FCC |

| Melting Point (°C) | 660.2 |

| Boiling Point (°C) | 2480 |

| Mean Specific Heat (0-100°C) (cal/g.°C) | 0.219 |

| Thermal Conductivity (0-100°C) (cal/cms. °C) | 0.57 |

| Co-Efficient of Linear Expansion (0-100°C) (x10-6/°C) | 23.5 |

| Electrical Resistivity at 20°C (Ω.cm) | 2.69 |

| Density (g/cm3) | 2.6898 |

| Modulus of Elasticity (GPa) | 68.3 |

| Poisson’s Ratio | 0.34 |

Aluminium Profiles:

SPECIFICATONS:

Thickness : 0.71-1.22 mm

Length : As per requirements

Width : As per Profile

Finish : Plain Mill, Stucco, Color Coated

Color : As Per Availability

Grade : H14, H18,

Advantages:

Mechanical Properties Of Aluminium Alloys:

| ALLOY | TEMPER | TENSILE STRENGTH(MPa) | ELONGATION % MINIMUM (50 MM GAUGE LENGTH) | |||

|---|---|---|---|---|---|---|

| MIN | MAX | 0.50 - 0.80 MM | 0.80 - 1.30 MM | >1.30 MM | ||

| 1100/1200 | H12 | 95 | 130 | 3 | 5 | 8 |

| 1100/1200 | H14 | 110 | 145 | 2 | 4 | 5 |

| 1100/1200 | H16 | 130 | 165 | 2 | 3 | 4 |

| 1100/1200 | H18 | 150 | - | 2 | 2 | 3 |

| 8011 | 0 | 85 | 120 | 20 | 23 | 25 |

| 8011 | H12 | 105 | 140 | 5 | 6 | 7 |

| 8011 | H14 | 125 | 160 | 3 | 4 | 5 |

| 8011 | H16 | 150 | 180 | 2 | 3 | 4 |

| 8011 | H18 | 175 | - | 2 | 2 | 3 |

Chemical Composition Of Aluminium Alloys:

| CHEMICAL COMPOSITION LIMITS (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| % Si | % Fe | % Cu | % Mn | % Mg | % Cr | % Zi | % T | (Others) | (Others) Total | % Al | |

| 1100 | 0.90 (Si+Fei) | 0.05 – 0.20 | 0.05 | - | - | 0.10 | - | 0.05 | 0.015 | 99.00 (Min) | |

| 1200 | 00 (Si+Fe) | 0.05 | 0.05 | - | - | 0.10 | 0.05 | 0.03 | 0.015 | 99.00 (Min) | |

| 8011 | 0.60-0.95 | 0.20 | 0.10 | 0.10 | - | 0.20 | 0.20 | 0.05 | 0.15 | 98.00 (Min) | |